The Challenge

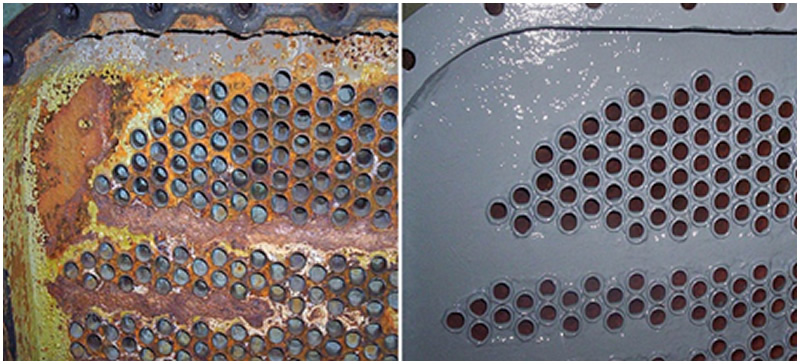

Leakage in critical pieces of equipment such as heat exchangers tube sheets, due to galvanic corrosion as well as chemical attack and erosion.

The Solution

MRO INFRA provides a variety of solvent free metal repair composites and Novalac epoxy coating and Brushable Ceramic coating for repair and protection of critical pieces of equipment such as heat exchangers. Areas including tube sheets, water boxes, flange faces, division bars and end covers can be protected against galvanic corrosion as well as chemical attack. Our cold curing epoxy products allow for rapid, in-situ application minimizing downtime whilst providing long-term erosion and corrosion protection. MRO INFRA materials are excellent electrical insulators, which enables them to prevent galvanic corrosion by isolating the dissimilar metals used in heat exchangers.

Heat exchanger restoration

Heat exchangers can be repaired using cold applied metal repair composites like MRO 8000 Ti PUTTY and MRO 3003 BRUSHABLE CERAMIC/ MRO 3000 CHEMPRO that will not only rebuild heat exchangers components to their original profile, but will also:

- Provide long-term erosion and corrosion resistance

- Eliminate galvanic corrosion

- Prevent crevice corrosion

- Minimize equipment downtime

- Provide high temperature resistance

- Offer outstanding chemical resistance against a wide range of chemicals

- Eliminate the need for hot work

- Reduce expensive replacement costs

- Extend equipment life

The Result

WHY MRO ...?

APPLICATION CASE HISTORY CIPLA – VERNA GOA

PROBLEM:

Leakage in chiller heat exchangers tube sheets, due to galvanic corrosion as well as chemical attack.

CUSTOMERS BENEFIT:

With minimal investment in ‘MRO 3000 CHEMPRO’ reliable repair that cuts overall costs and downtime

JOB COMPLETION:

May, 2019